The Danger Zone Explained: Why Temperature Control is Key in Australia’s Climate

Australia, with its vast and varied landscapes, experiences a wide range of climates, from the scorching deserts of the Outback to the humid tropics of the north.

This diverse climate presents unique challenges for food safety, making temperature control a critical aspect of food handling for businesses across the country.

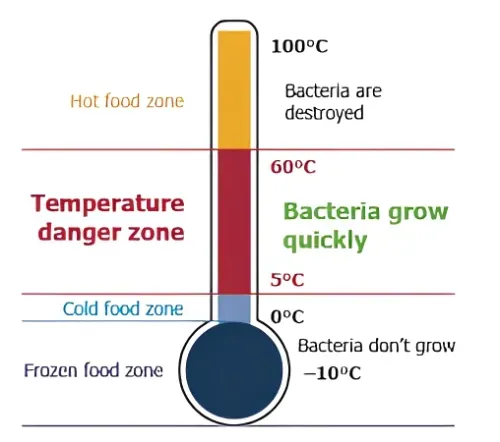

Whether you’re running a café in Melbourne or a processing plant in Darwin, understanding the risks of food falling into the "danger zone" (between 5°C and 60°C) is essential.

The Danger Zone: Why Temperature Matters

The "danger zone" for food is generally considered to be between 5°C and 60°C. Within this range, bacteria multiply at an alarming rate. In Australia, especially during the summer months, it's crucial to minimize the time food spends in this zone.

Properly storing, cooking, and serving food at safe temperatures is essential for preventing foodborne illnesses. The Australian government through Food Standards Australia New Zealand (FSANZ) provides vital information regarding food safety and temperature control.

"Temperature control is one of the most important factors in preventing food poisoning," states FSANZ. You can find more detailed information on their website:

Food Standards Australia New Zealand - Temperature control

Key Principles of Temperature Control

To navigate the challenges of Australia's climate and ensure food safety, businesses must adhere to these key principles:

2-Hour/4-Hour Rule:

In food manufacturing, temperature control is crucial to prevent the growth of harmful bacteria. The 2-hour/4-hour rule is a guideline that helps manage the safety of potentially hazardous foods when they are within the temperature range known as the "danger zone" (between 5°C and 60°C).

Understanding the 2-Hour/4-Hour Rule:

- 0 to 2 hours: Food can be used immediately or returned to refrigeration.

- 2 to 4 hours: Food can still be used but should not be refrigerated again. foodauthority.nsw.gov.au

- More than 4 hours: Food must be discarded.

Application in Food Manufacturing:

In a manufacturing setting, it's essential to monitor how long food spends in the danger zone during various processes:

- Preparation and Processing: Ensure that the combined time food spends between 5°C and 60°C during preparation and processing does not exceed 4 hours.

- Cooling Cooked Foods: After cooking, foods should be cooled from 60°C to 21°C within 2 hours and then from 21°C to 5°C within the next 4 hours. foodstandards.gov.au+1foodstandards.gov.au+1

- Thawing: Foods should be thawed in the refrigerator, under cold running water, or in the microwave, and not at room temperature, to prevent them from entering the danger zone for extended periods.

Cold Storage:

- Store perishable foods at or below 5°C.

- Use calibrated thermometers to ensure your refrigerators and freezers are maintaining the correct temperatures.

Hot Holding (cafe’s, restaurants & catering situations):

- Keep hot foods at or above 60°C.

- Use chafing dishes, steam tables, or other appropriate equipment to maintain these temperatures.

- Adhere to the 2-hour/4-hour

Cooking Temperatures:

- Cook foods to the recommended internal temperatures to kill harmful bacteria.

- Use a food thermometer probe (rather than infrared sensing) to check the internal temperature of meats, poultry, and other foods.

- Ensuring pasteurisation times and temperatures are achieved and documented

Cooling Food:

- Cool cooked foods quickly to minimize the time they spend in the danger zone.

- Divide large portions into smaller containers and refrigerate or freeze them promptly.

- Frequent stirring

- Adhere to the 2-hour/4-hour rule

Thawing Food:

- Thaw frozen foods safely overnight in the refrigerator, or in the microwave.

- Never thaw food at room temperature.

Practical Tips for Australian Food Businesses:

Here are some practical tips to help Australian food businesses maintain proper temperature control:

- Invest in Reliable Equipment: Use calibrated thermometers, refrigerators, freezers, and hot holding equipment that accurately maintain temperatures.

- Implement a HACCP Plan: Develop a Hazard Analysis Critical Control Point (HACCP) plan to identify and control temperature-related hazards.

- Train Your Staff: Ensure your staff are trained on proper temperature control procedures and understand the importance of food safety.

- Monitor and Record Temperatures: Regularly monitor and record refrigerator or freezer temperatures and pasteurisation or cooking times and temperatures. This documentation is crucial for food safety audits.

- Consider the Australian Climate: Adjust your food safety practices based on seasonal temperature and humidity fluctuations. Pay extra attention during hot and humid summer months.

ASKAFOODTECH: Your Partner in Food Safety

Maintaining proper temperature control is essential for safeguarding your customers and your business's reputation. By adhering to best practices and staying informed about the latest guidelines, you can ensure that your food remains safe, regardless of the Australian climate.

Contact ASKAFOODTECH today to learn how we can help your business thrive while maintaining the highest food safety standards.

About the Author:

Stewart Eddie (Bapp Sc Food Science & Technology) is Director and Principal Food Tech at ASKAFOODTECH PTY LTD; a food technology consulting company that inspires, educates, and serves food producers with an ambition to grow and manage risk. Living with a severe food allergy and being a food technologist, Stewart is uniquely placed to help your food manufacturing business with your allergen management planning. If you would like more information on the services that ASKAFOODTECH PTY LTD can provide, please

contact us.